The 0533205 pressure switch has become one of the most dependable components used in modern industrial and mechanical systems. In the first paragraph, it is essential to highlight that the 0533205 pressure switch delivers outstanding accuracy, durability, and performance—making it a preferred choice for engineers, HVAC professionals, and manufacturing industries. This guide explains how the switch works, where it is used, and why it has become an essential part of pressure-based automation systems.

Understanding the 0533205 Pressure Switch

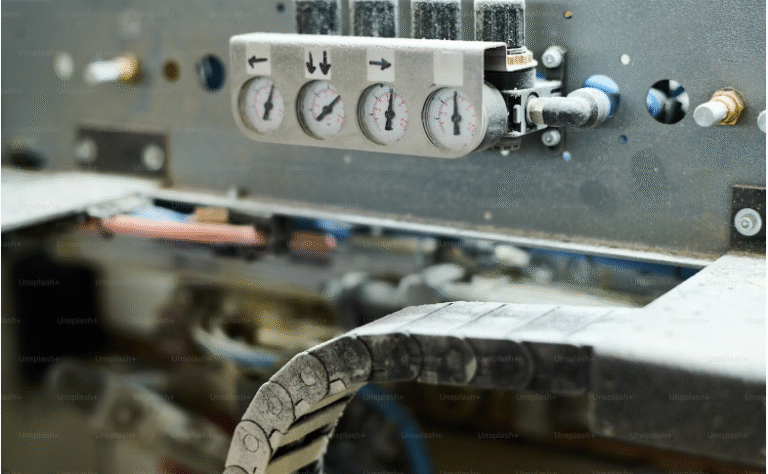

A pressure switch is a critical device that monitors fluid or air pressure and triggers a specific action when pressure levels exceed or fall below predefined limits. The 0533205 pressure switch is designed with enhanced sensitivity and stability to ensure flawless operation in demanding industrial environments.

Its primary purpose is to detect pressure deviations and activate a response such as turning equipment on or off, opening valves, or initiating alarms. This makes the switch vital for maintaining efficiency, safety, and system reliability.

How the 0533205 Pressure Switch Works

The 0533205 pressure switch functions based on a simple yet effective mechanism:

1. Pressure Detection

A diaphragm or piston inside the switch senses pressure changes. When the internal pressure reaches the set limit, it pushes against a mechanical or electronic sensor.

2. Electrical Contact Activation

Once the pressure threshold is hit, electrical contacts close or open, depending on whether the system requires activation or shutdown.

3. Controlled Output

The switch sends a signal to the connected equipment, such as:

-

Compressors

-

Pumps

-

Air conditioning units

-

Industrial machines

-

Safety alarms

This automated response prevents system failures, overheating, low-pressure hazards, and unnecessary energy consumption.

Key Features of the 0533205 Pressure Switch

The 0533205 pressure switch stands out due to its advanced engineering. Here are its most notable features:

• High Accuracy and Stability

The switch ensures precise pressure control, which is crucial in applications requiring stable operational ranges.

• Durable Construction

Its rugged build allows it to withstand harsh environments, vibration, high temperatures, and pressure fluctuations.

• Wide Pressure Range

The adjustable pressure range makes it suitable for multiple industries and machinery types.

• Easy Installation

Pre-configured calibration and universal mounting options help technicians set up the switch quickly.

• Long Lifespan

Thanks to reinforced diaphragms and corrosion-resistant components, the switch offers long-term reliability.

• Compatible With Various Fluids

From air and water to hydraulic oils and refrigerants, the switch performs efficiently with different media.

Common Applications of the 0533205 Pressure Switch

The 0533205 pressure switch is used in a wide range of industrial and mechanical systems. Some common applications include:

1. HVAC Systems

In heating, ventilation, and air conditioning units, the switch helps control airflow, refrigerant pressure, and overall safety.

2. Air Compressors

It maintains consistent pressure levels by automatically turning the compressor on or off, preventing equipment overload.

3. Water Pumps

The 0533205 pressure switch keeps water systems operating efficiently by regulating pump activation based on pressure levels.

4. Industrial Manufacturing

Many automated production lines rely on the switch for maintaining optimal hydraulic and pneumatic pressure.

5. Safety and Alarm Systems

When pressure becomes unsafe, the switch triggers alarm systems to prevent hazards.

Benefits of Using the 0533205 Pressure Switch

Using the 0533205 pressure switch offers several advantages that improve system efficiency and safety:

• Enhanced Equipment Protection

It prevents machinery damage caused by excessive or inadequate pressure.

• Reduced Energy Consumption

Automatic activation and deactivation ensure that equipment runs only when needed.

• Lower Maintenance Costs

Its reliable design reduces breakdowns and extends the lifespan of compressors, pumps, and HVAC units.

• Increased Workplace Safety

Accurate pressure regulation minimizes the risk of operational accidents.

• Improved System Performance

Stable pressure control enhances productivity and ensures consistent output.

Installation Tips for the 0533205 Pressure Switch

For optimal performance, proper installation is essential. Here are some important tips:

1. Choose an Accessible Location

Mount the switch where it’s easy to inspect and service without shutting down the entire system.

2. Check Pressure Ratings

Ensure that the pressure range matches your application to avoid malfunction or premature failure.

3. Use Quality Connectors

Secure fittings and seals prevent leaks and ensure accurate pressure readings.

4. Follow Manufacturer Guidelines

This includes torque specifications, wiring instructions, and calibration standards.

Troubleshooting the 0533205 Pressure Switch

Even high-quality components can face occasional issues. Here are common problems and solutions:

• Issue: Switch Not Activating

Cause: Incorrect pressure setting or clogged inlet

Solution: Adjust settings and clean the pressure port

• Issue: Rapid On/Off Cycling

Cause: System pressure imbalance

Solution: Check for leaks or faulty check valves

• Issue: Inaccurate Pressure Readings

Cause: Damaged diaphragm or misalignment

Solution: Replace the diaphragm or recalibrate

• Issue: Electrical Failure

Cause: Loose wiring or burnt contacts

Solution: Inspect wiring, clean contacts, or replace components

Maintenance Guide for Long-Term Performance

To extend the lifespan of the 0533205 pressure switch, regular maintenance is recommended.

-

Inspect the switch monthly for dirt and debris

-

Check wiring and terminals for corrosion

-

Verify that pressure readings match system requirements

-

Recalibrate during seasonal equipment maintenance

-

Keep the switch in a stable environment with minimal vibration

Proper care ensures consistent reliability and prevents costly breakdowns.

Conclusion

The 0533205 pressure switch is an essential component that ensures reliable pressure monitoring and automatic control in a wide range of applications. With its durable construction, precise performance, easy installation, and long lifespan, it has become a trusted solution for HVAC systems, manufacturing units, air compressors, and more. By understanding its features, maintenance requirements, and troubleshooting methods, users can maximize system efficiency and avoid unexpected failures. Whether you’re an engineer, technician, or equipment operator, investing in a high-quality pressure switch like the 0533205 pressure switch is a smart choice for long-term operational success.

FAQs About the 0533205 Pressure Switch

1. What is the 0533205 pressure switch used for?

It is used to monitor and control pressure levels in HVAC systems, compressors, pumps, and industrial equipment.

2. How do I adjust the pressure settings?

Most models have an adjustable screw or knob that allows you to modify the pressure cut-in and cut-out levels.

3. Can the 0533205 pressure switch handle different fluids?

Yes, it is compatible with air, water, refrigerants, and some hydraulic oils depending on the model.

4. How long does this pressure switch typically last?

With proper maintenance, it can last several years due to its durable and corrosion-resistant design.

5. Why is my pressure switch cycling too frequently?

Frequent cycling is usually caused by system leaks or incorrect pressure settings. Inspect the system and adjust as needed.